Raw Material for Rigid Foam Polyurethane Polyether Polyol + Polymeric MDI ,PAPI with ISO Certificate

Raw Material for Rigid Foam Polyurethane Polyether Polyol + Polymeric MDI ,PAPI with ISO Certificate

Raw Material for Rigid Foam Polyurethane Polyether Polyol & Iso

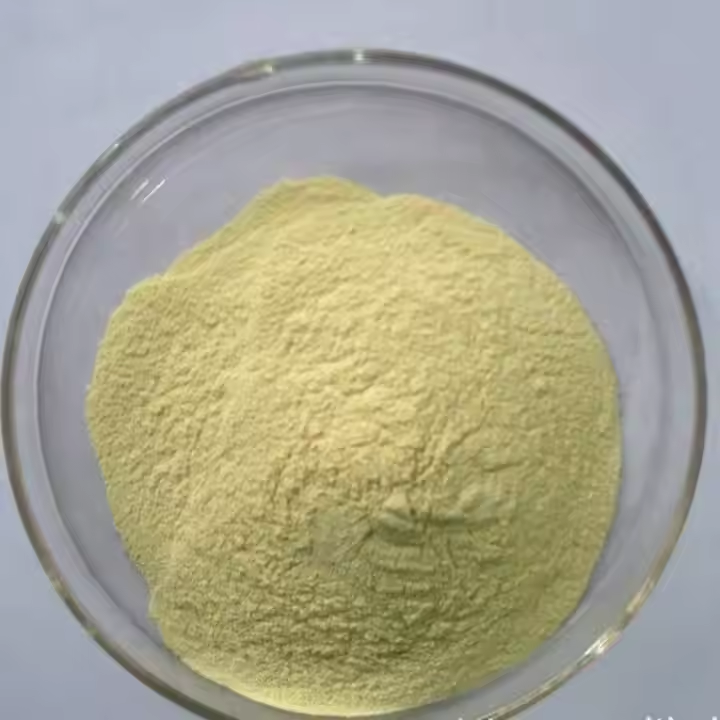

DQT-501C is spray blend polyols, blowing agent is 365mfc/245fa instead of HCFC-141B, it reacts with iso to produce foam which has excellent performances, which are as follows:

1) fine and uniformity cells

2) low thermal conductivity

3) perfect fla-me resistance

4) good low temperature dimensional stability.

It applies to all kinds of thermal insulation engineering which uses the spray technology, such as cold rooms, pots, large-scale pipelines and construction metope etc.

Parameter of Double Component Polyurethane Foam Material

Raw Material for Rigid Foam Polyurethane Polyether Polyol & Iso-cyanate

Physical Properties

Appearance Hydroxyl Value mgKOH/g Dynamic Viscosity (25 ℃) mpa.s Specific gravity (20 ℃ ) g/ml Storage Temperature ℃ Storage Stability month | Pale yellow to brown viscous liquid 200-300 100-200 1.12-1.20 10-25 6 |

Recommended Ratio

pbw | |

DJD-105 blend polyols iso-cyanate | 100 100-105 |

Reactivity Characteristics

(The temperature of the system is 20℃,and the exact value varied depending on processing condition)

Cream Time s Gel Time s | 3-5 6-10 |

Foam Performances

items | Test Method | Index |

Spray Density Closed-cell Rate Initial Thermal Conductivity(15℃) Compressive Strength Adhesive Strength Elongation at break Dimentional Stability 24h -20℃ 24h 70℃ Water Absorption Oxygen Index | GB 6343 GB 10799 GB 3399 GB/T8813 GB/T16777 GB/T9641 GB/T8811

GB 8810 GB 8624 | >40kg/m3 ≥90% ≤24mW/(m.K) ≥150kPa ≥120kPa ≥10% ≤1% ≤1.5% ≤3% ≥26 |